IND ETO C1445 Industrial Ethylene Oxide Gas Sterilization Devices Brochure EN - Pdf 692 Kb.

IND ETO C1445 Industrial Ethylene Oxide Gas Sterilization Devices Catalogue EN - Pdf 9166 Kb.

| ISO 9001 | ISO 13485 | CE 1984 |

IND ETO C1445 Industrial Ethylene Oxide Sterilizer Data Sheet EN - Pdf 529 Kb.

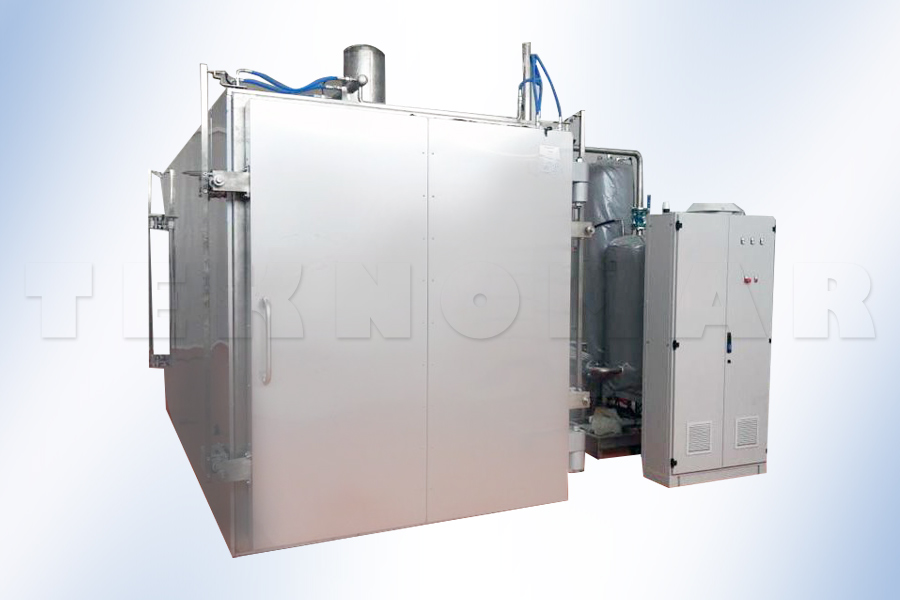

Industrial Type ETO Sterilizer ETO-C 1445 is the best solution partner for medical equipment manufacturers. Many of the items which are sensitive to heat and moisture can be sterilized with EO gas Sterilization. Bulk product manufactures usually cannot find the best choice for sterilizing their products. ETO-C 1445 comes with different M3 options and will be your main asset of your production line.

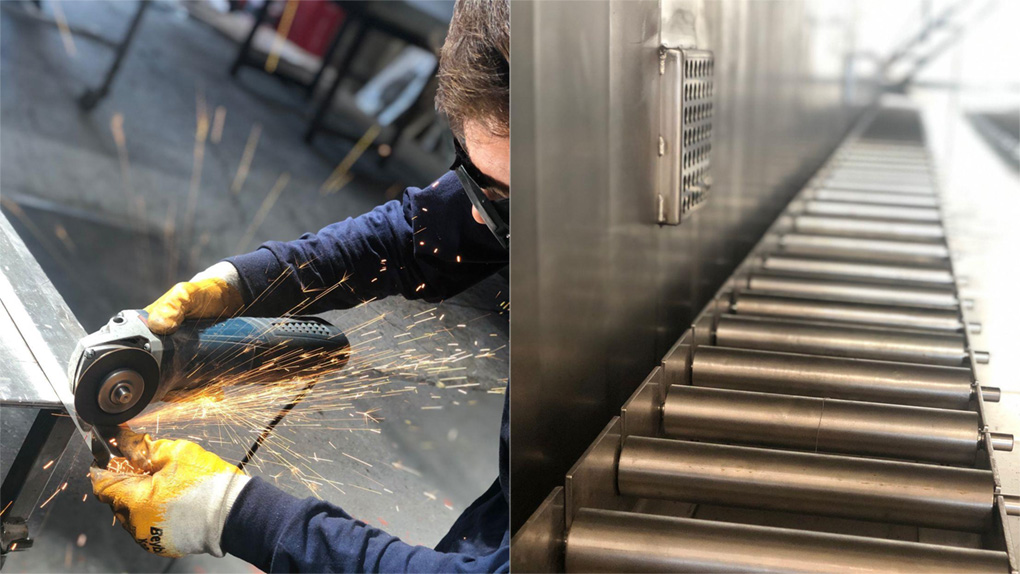

Teknomar Ltd facilitates the senior engineers and technicians for the professional projects. Tailored manufacturing is made by our highest grade of stainless steel materials and find a way of magnificant products.

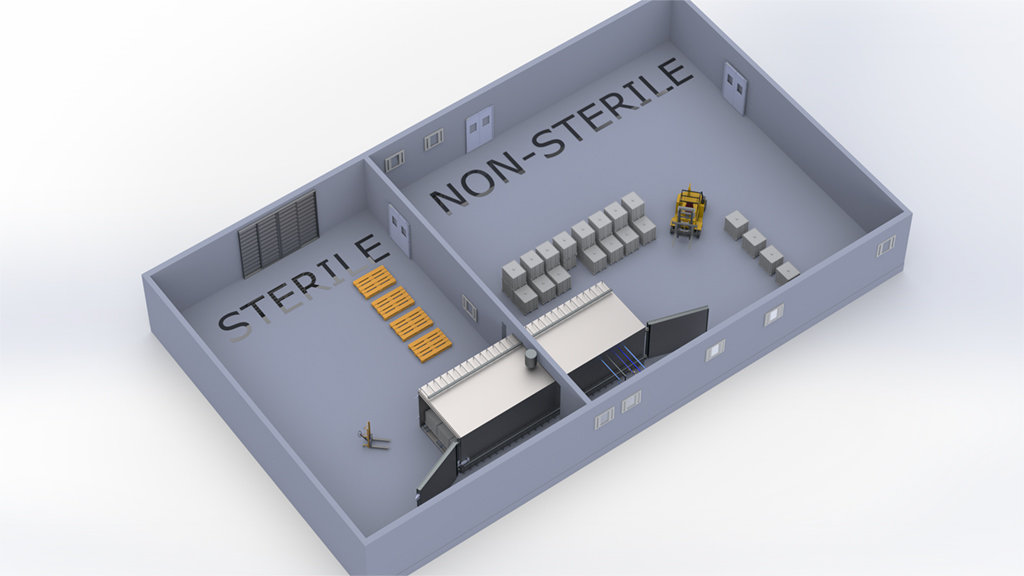

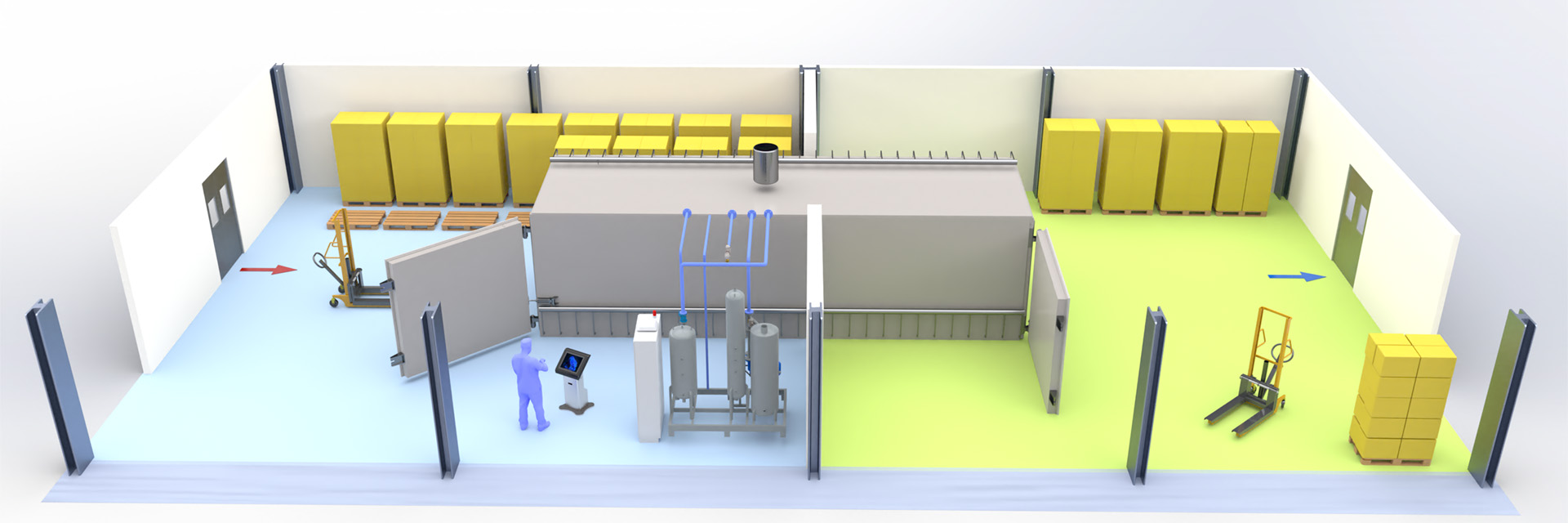

IND ETO C1445 Industrial Type Ethylene Oxide Device Loading & Unloading With Pallet

Teknomar Ltd chases customer orianted approach to become the best solution partner. ETO-C 1445 has the most important role in your manufacturing end. Sterilization should be considered the first and most significant stage of the manufacturing.

Teknomar Ltd is experienced in different product sterilizations such as : medical disposable items, absorbable and non-absorbable sutures, catheters, laparoscopic surgical instruments, implants, sensitive flexible medical items, endoscposes, rigid and semi-rigid lumen shaped tools.

Superior Feature:

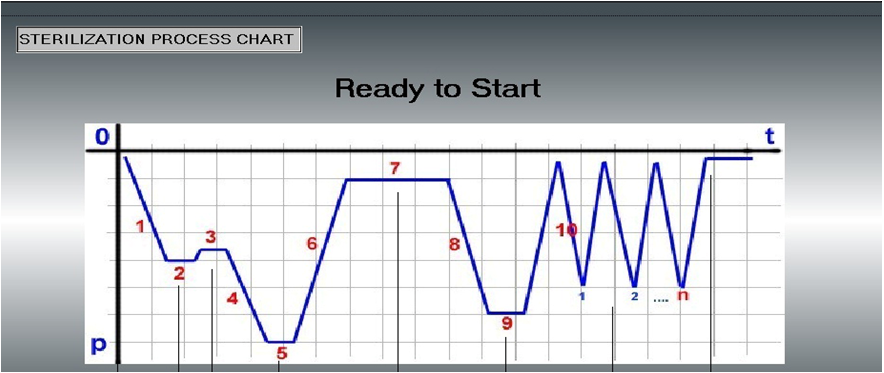

Pre-conditioning, Gassing and Aeration is done in the same chamber in Teknomar END ETO C1445 Sterilization Device.

Different Gas Mixtures Can Be Selected According to the Material Validation. Some of them;

| Industrial Type EO Sterilization Device C-1445 | Ethylne Oxide Sterilization Device Chamber Inner Dimensions |

Weight (~kg) |

Power (kW) | ||||

| Chamber Volume (~m3) | Euro Pallet | Door | Width (cm) | Depth (cm) | Height (cm) | ||

| 0,5 Suture | - | Single | 82,5 | 74 | 82,5 | 960 | 10 |

| 1 | - | Single | 90 | 110 | 100 | 1450 | 21 |

| 1,6 Suture | - | Single | 90 | 158 | 113 | 2000 | 25 |

| 1,6 Suture | - | Double | 90 | 158 | 113 | 2000 | 25 |

| 2,1 Suture | - | Single | 90 | 160 | 140 | 2500 | 30 |

| 2,1 Suture | - | Double | 90 | 160 | 140 | 2500 | 30 |

| 2 | - | Single | 120 | 120 | 140 | 1900 | 25 |

| 5 | - | Single | 135 | 275 | 135 | 2800 | 50 |

| 6 | 2 | Single | 135 | 190 | 235/240 | 3500 | 50 |

| 6 | 2 | Double | 135 | 190 | 235/240 | 3500 | 50 |

| 10 | 4 | Single | 180 | 260 | 220 | 5800 | 60 |

| 10 | 4 | Double | 180 | 260 | 220 | 5800 | 60 |

| 15 | 6 | Single | 180 | 390 | 220 | 6600 | 70 |

| 15 | 6 | Double | 180 | 390 | 220 | 6600 | 70 |

| 20 | 8 | Double | 180 | 520 | 220 | 8500 | 70 |

| 27 | 10 | Double | 180 | 640 | 235/240 | 10000 | 75 |

| 34 | 12 | Double | 180 | 780 | 240 | 12000 | 80 |

| 40 | 14 | Double | 260 | 640 | 240 | 14500 | 100 |

| 44 | 16 | Double | 260 | 705 | 240 | 15500 | 110 |

| 50 | 18 | Double | 260 | 800 | 240 | 17000 | 120 |

| 62,5 | 24 | Double | 260 | 1010 | 240 | 21000 | 140 |

| 62,5 | and more… | ||||||

* The above dimensions show the standard production. The custom sized manufacturing is available, Please contact to your representative for more information.

* Pallet size: EURO 80 X 120 cm

Teknomar Ltd facilitates the senior engineers and technicians for the professional projects. Tailored manufacturing is made by our highest grade of stainless steel materials and find a way of magnificant products.

Teknomar Ltd chases customer orianted approach to become the best solution partner. ETO-C 1445 has the most important role in your manufacturing end. Sterilization should be considered the first and most significant stage of the manufacturing.

ETO - C 1445 has a compact design built-in one shape in order to utilize the user for a multifunctional purposes. Device enables the user to program different parameters for multiple products' sterilization.

In previous experiences, users were having material preconditionings and aearations within another chamber. This increases the time of sterilization, cost of sterilization and work load for the employees. However, ETO-C 1445 introduces a new technique where preconditioning, gassing and aeration are done by only one chamber.

ETO - C 1445 cuts the whole possible costs to give you the optimized economies of scale. Teknomar Ltd gives you the validation and calibration services for different unique materials. Although the average sterilization duration is 6 hours, this duration could be lower or higher depending on FAT to the material to be sterilized.

Teknomar Ltd assigns its best technicians to adjust the device for optimized level of sterilization considering the costs and sterilization accuracy.

ETO - C 1445 requires periodical maintances daily, semi-annually and annually. Maintanence will be applied by the authorized person. Spare parts are supplied with speficied maintanence kits periodically.

Teknomar Ltd gives design, manufacturing, installation, training and relevant services for its customers. Most of the productions take 8-10 weeks to accomplish. We are able to install your sterilizer in any part of the World. Please contact your representative for more details.

Information Form

Top of Page

Warnings: